This set of tests is aimed at understanding the effect of different finishes on Ovangkol.

A set of 13 consecutive veneer sheets (from “A” to “M”) were employed; these consecutive layers of the initial log and start from very similar PZC values. All samples were sanded to 240-grit.

A special thanks goes to company Seralvo for providing the veneer samples and Veleca for supporting us with finish samples.

We tested these finishes:

Sample A: Veleca Palkerol (water based anionic polyurethane – floor finish)

Sample B: Veleca Pinteco (acrylic emulsion – outdoor finish)

Sample C: Veleca Mobil H (water based acrylic – furniture finish)

Sample D: Veleca Nitrolux (thinner based ketone resin – classic furniture finish)

Sample E: Veleca Tampoval (blonde dewaxed shellac – antique furniture finish)

Sample F: Veleca Olio per Teak (Tung oil based – exotic wood finish)

Sample G: Boiled Linseed Oil (BLO)

Sample H: Furniture restoring oil

Sample I: Nitrocellulose spray lacquer (NCL)

Sample J: Acrylic spray lacquer

Sample K: Blonde Dewaxed Shellac “Medium” (2 parts in 13 parts of Alcohol)

Sample L: Transparent epoxy resin

Sample M: A more complex sequence: sanding to #800, then pore filling with epoxy, then sanding to #10’000, then Veleca Nitrolux

Sample N: Rubio Monocoat

It was concluded that:

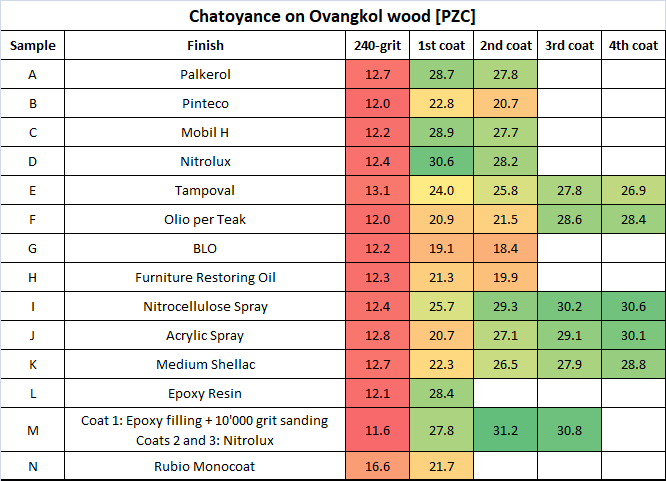

1) Chatoyance is significantly increased by some of these clear coats

2) Nitrolux, Nitrocellulose or Acrylic lacquers provide the best results

3) The complex procedure applied on sample M did not yield significant advantages

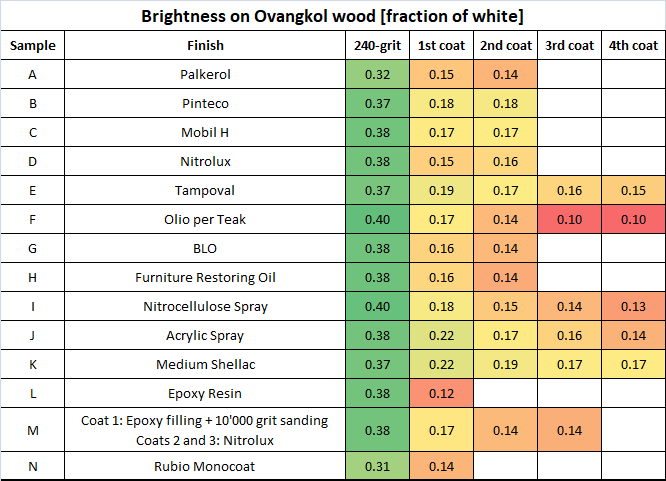

3) Some of these “clear” finishes significantly darken the surface

Tables below summarize the results in terms of chatoyance (PZC):

Tables below summarize the results in terms of brightness (fraction of white paper brightness):

Pictures below show the results: