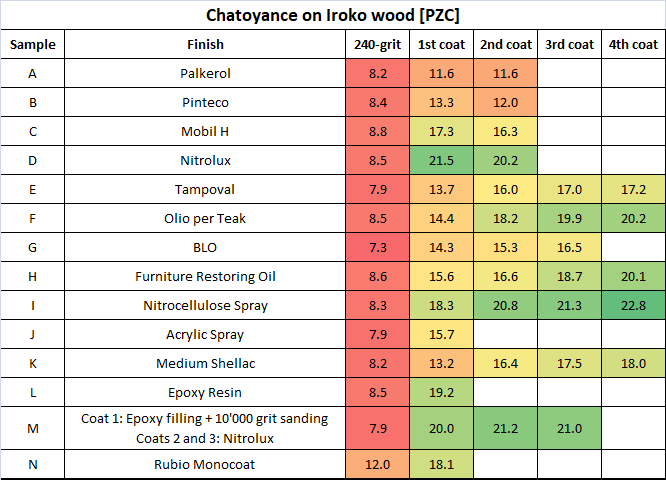

This set of tests is aimed at understanding the effect of different finishes on Iroko.

A set of 13 samples (from “A” to “M”) were obtained from 5 consecutive and uniform veneer sheets; these all start from very similar PZC values. All samples were sanded to 240-grit.

A special thanks goes to company Seralvo for providing the veneer samples and Veleca for supporting us with finish samples.

We tested these finishes:

Sample A: Veleca Palkerol (water based anionic polyurethane – floor finish)

Sample B: Veleca Pinteco (acrylic emulsion – outdoor finish)

Sample C: Veleca Mobil H (water based acrylic – furniture finish)

Sample D: Veleca Nitrolux (thinner based ketone resin – classic furniture finish)

Sample E: Veleca Tampoval (blonde dewaxed shellac – antique furniture finish)

Sample F: Veleca Olio per Teak (Tung oil based – exotic wood finish)

Sample G: Boiled Linseed Oil (BLO)

Sample H: Furniture restoring oil

Sample I: Nitrocellulose spray lacquer (NCL)

Sample J: Acrylic spray lacquer

Sample K: Blonde Dewaxed Shellac “Medium” (2 parts in 13 parts of Alcohol)

Sample L: Transparent epoxy resin

Sample M: A more complex sequence: sanding to #800, then pore filling with epoxy, then sanding to #10’000, then Veleca Nitrolux

Sample N: Rubio Monocoat

It was concluded that:

1) Even if Iroko is generally a high-chatoyance wood, the results achieved here are quite low

2) chatoyance is significantly increased only by some of these clear coats

2) Nitrolux, Teak il, Furniture restoring oil and Nitrocellulose lacquer provide the best results

3) Nitrocellulse lacquer even exceeds the results achieved with the complex procedure applied onto sample M

4) Some of these “clear” finishes significantly darken the surface

Tables below summarize the results in terms of chatoyance (PZC):

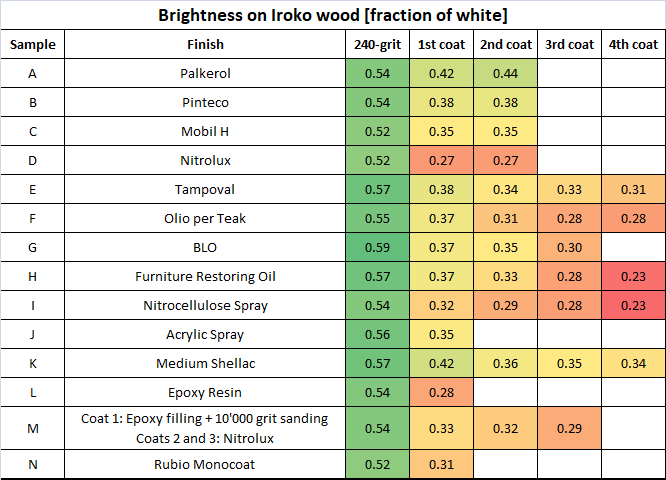

Tables below summarize the results in terms of brightness (fraction of white paper brightness):

Pictures below show the results: